Auger Torque announces addition of Kinshofer Drum Cutter

Auger Torque announces the addition of the Kinshofer Drum Cutter range to its portfolio of products.

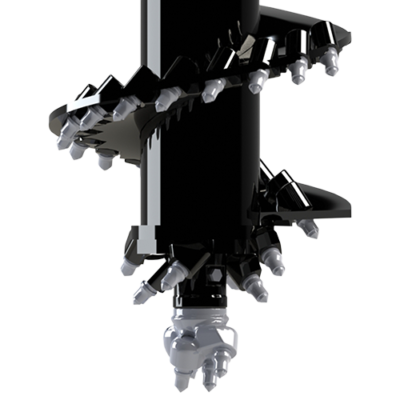

Brisbane, Australia – March 2023 – Auger Torque announces the addition of the Kinshofer Drum Cutter range to its portfolio of products. Originally a Kinshofer product, Auger Torque is excited to take over the manufacturing, development, sales and support for this attachment range globally.

This range of drum Cutters are available in nine models suitable for 2 to 60 ton excavators, featuring an exclusive pick angle and optimal chisel arrangement for high performance and minimal wear, makes these attachments ideal for mining, tunnelling, road construction and demolition. The attachment’s heavy-duty sealing system enables underwater operation as deep as 25 meters for applications such as bridge repair.

This series boast being one of the quietest in the industry, making them excellent for use in areas with noise restrictions. They also produce lower vibration levels, so contractors can use them where there’s a risk of disturbing a nearby structure’s foundation.

The low decibel output and minimal vibrations of the attachments is achieved through a high-torque hydraulic motor. The motor powers the drum cutter while its gear reduction optimizes torque and cutting force. The higher torque enables the attachment to achieve greater cutting efficiency while operating at a slower speed than competitive drum cutters. The controlled speed of the attachment reduces noise and vibration as well as maximizes operator comfort. Additionally, the hydraulic motor is adjustable to match the output of an excavator’s hydraulics.

There are various drum options, depending on the application. The rock drum breaks soft to medium-hard rock in mines and quarries with its strategic chisel pattern while the profiling drum’s higher density of chisels shapes and levels soft to medium-hard rock in tunnelling applications. The demolition drum offers reduced vibrations due to a wear-protected spiral sheet and is ideal for cutting medium-hard to hard rock as well as concrete.

Again to suit the application, there are four chisel tips that attach to the wear pick: standard, heavy-duty, wear-protected and wood. Standard chisels are excellent for breaking asphalt, argillite and other soft to medium-hard rocks while the heavy-duty chisels power through medium-hard to very-hard materials such as limestone and concrete. Wear-protected chisels are ideal for abrasive rocks such as sandstone and furnace gravel. The wood chisel is designed specifically for wood applications, such as stump removal. Wear picks can be replaced in minutes, leading to greater productivity and less downtime.

Selecting the proper chisel and drum combination is key to optimizing performance and reducing attachment wear, therefore the Auger Torque team work closely with customers to understand applications and material conditions so they can recommend the best drum and chisel tip for each situation.

Alistair Brydon, Managing Director at Auger Torque, “The KDC drum cutters are the ideal attachment to scale rock or concrete walls, tunnel excavation, trenching in extreme grounds or loosen any hard rocky ground in the most efficient way. We believe there is a real need for this kind of attachment all around the world and we are excited to launch this new attachment to all our customers around the globe”

Earth Drills

Earth Drills  Augers & Extensions

Augers & Extensions  Screw Pile Torque Heads

Screw Pile Torque Heads  Hard Rock Augers

Hard Rock Augers  Trenchers

Trenchers  Variable Mulchers

Variable Mulchers  TC Range Mulchers

TC Range Mulchers  Hedge Trimmer

Hedge Trimmer  Cone Crusher Bucket

Cone Crusher Bucket  Drum Cutters

Drum Cutters  Log Splitter

Log Splitter  Stump Planer

Stump Planer  Cement Mixer Bowls

Cement Mixer Bowls  Pallet Forks

Pallet Forks  Alignment Monitor

Alignment Monitor  Aluminum Ramps

Aluminum Ramps