Abbey Pynford screw pile installation

Three problems. One Solution – Auger Torque. Specialists in piling, underpinning and foundations, Abbey Pynford were tasked with an installation which would require a high torque output in a compact design. Various manufacturers were approached to supply the equipment, but nothing quite had the power required.

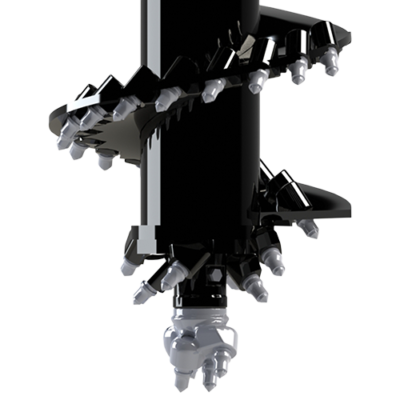

The solution was found when they contacted Neil Beard of Auger Torque Europe. From their large range of earth drilling and trenching attachments, and through their extensive experience of supplying the piling industry, Auger Torque recommended the Earth Drill 42000MAX. With 42,000 Newton Metres of torque it would easily produce enough power to drive the screw-piles to the required depth in a quick and efficient manner. The Earth Drill 42,000MAX is specifically designed for this kind of application and operates at a higher RPM than similar models in the range. Like all Auger Torque Earth Drills it uses a high quality & powerful hydraulic motor and is coupled to a bullet proof planetary gearbox of the company’s own unique design. The patented NDS (Non Dislodgement Shaft) technology, which is standard throughout the whole Auger Torque Earth Drill range, guarantees that the shaft will never fall out – a must-have-feature in today’s safety conscious age.

To manage and record the amount of torque being applied during installation, Abbey Pynford opted for a torque-monitoring device capable of monitoring forces up to 60.000Nm. The unit is fitted between the Earth Drill and parent machine and the torque is monitored via a constant wireless feed sending real time data back to a PDA or laptop.

Another challenge with this particular installation was having to keep the screw piles perfectly aligned while screwing them into the ground. The Auger Torque Alignment Monitor would solve this issue. A sensor, which is attached to the Earth Drill and the alignment monitor, which is fitted inside the cab of the Sany 21T excavator, ensured each screw pile stayed vertical and true without the need for an additional pair of eyes to guide the operator.

As an end result Abbey Pynford were entirely happy with the package supplied by Auger Torque, one could even say that their expectations were exceed. With the power, accuracy and compact size of the equipment, they were able to complete the project quickly and efficiently and without any problems or costly delays.

“For its compact size we couldn’t believe how much power the Auger Torque Earth Drill has and it was great to see that we never experienced pile refusal as we used to with other units we have trialled in the past”, David Kellet of Abbey Pynford concluded.

Now you’re talking!

Earth Drills

Earth Drills  Augers & Extensions

Augers & Extensions  Screw Pile Torque Heads

Screw Pile Torque Heads  Hard Rock Augers

Hard Rock Augers  Trenchers

Trenchers  Variable Mulchers

Variable Mulchers  TC Range Mulchers

TC Range Mulchers  Hedge Trimmer

Hedge Trimmer  Cone Crusher Bucket

Cone Crusher Bucket  Drum Cutters

Drum Cutters  Log Splitter

Log Splitter  Stump Planer

Stump Planer  Cement Mixer Bowls

Cement Mixer Bowls  Pallet Forks

Pallet Forks  Alignment Monitor

Alignment Monitor  Aluminum Ramps

Aluminum Ramps